For special stators with very complex motor designs or large diameters, automatic manufacturing solutions very quickly reach technical or economic limits. For these small series productions, Schaeffler ELMOTEC STATOMAT offers not only individually designed special tools, but also semi-automated special machines to support the manufacturing steps of insulating, winding and inserting.

- Stamping and cutting machine for slot insulations, intermediate slides and cover strips

- Production of slot base insulation and automatic insertion (EU/SIM series)

Insulation

The reliable insulation of stator windings with surface insulating materials is indispensable for the separation of electrical potentials to effectively dissipate heat loss for protection against overheating as well as for the mechanical fixation of the windings (closure of the stator slot). The so-called slot base insulation also serves to protect the winding wire from sharp edges of the stack of metal sheets.

- Controlled wire feeding

- Wire end and crack control

- Wear-free and unbreakable winding stencils

Winding

The automatic winding of coil groups for special three-phase motors (e.g. up to IEC size 250) places special demands on winding technology, wire guidance, control and flexibility of a coil winding machine. Schaeffler ELMOTEC STATOMAT winding machines are designed to produce even complex stators economically.

- Up to 60% time savings (depending on stator type)

- Consistent quality due to prevention of wire damage

Inserting

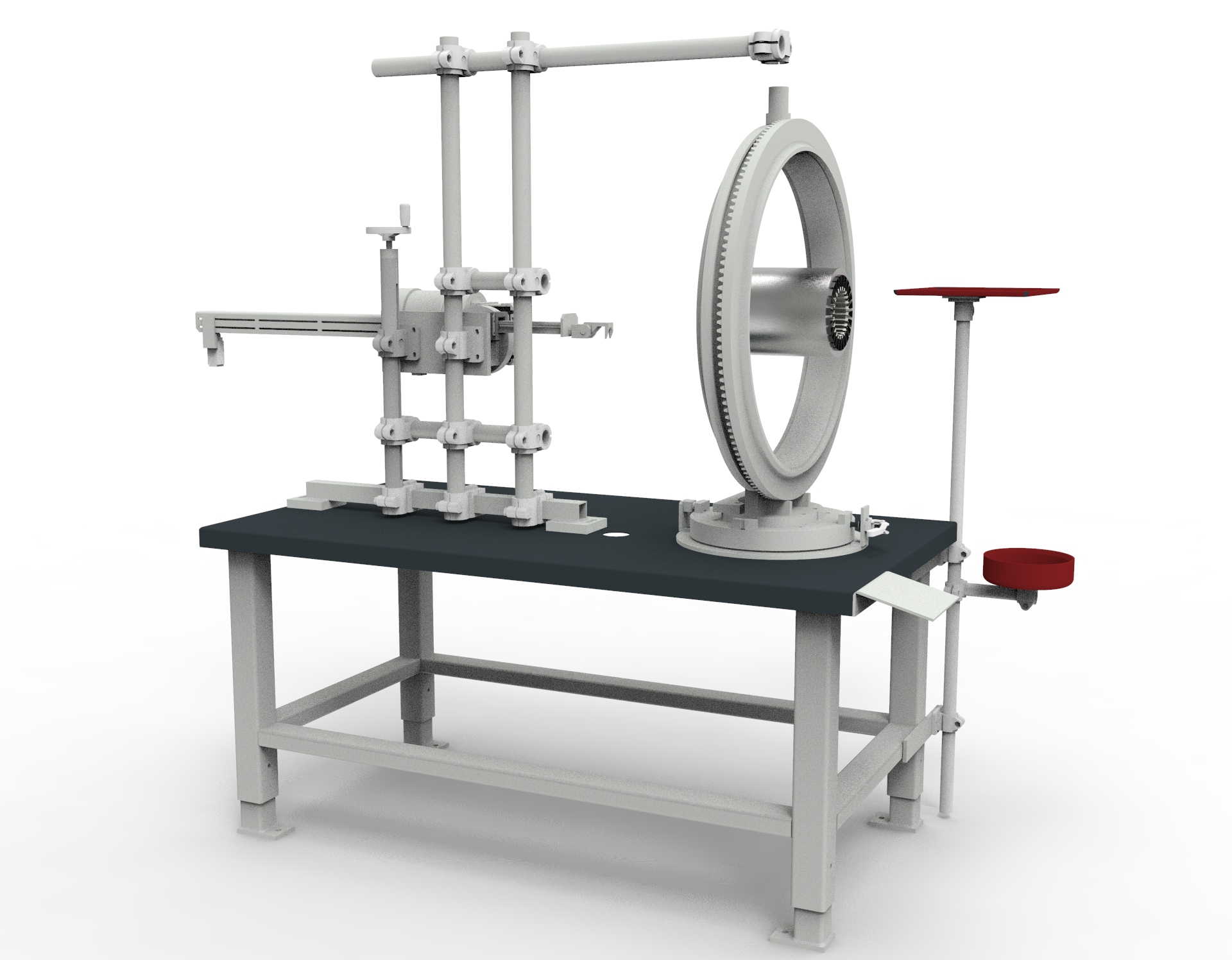

The individual and small series production of electric motors excludes the use of automatic coil winding machines. On the other hand, manual insertion of the coils is very time-consuming and cost-intensive. An economical solution to this problem is offered by the Schaeffler ELMOTEC STATOMAT coil insertion machines of the SEG / SEM series, which have been specially developed and proven for this area of application. These special machines are designed for IEC sizes 56-355 (also larger on request) and are designed, for example, for the manufacture of wind power generators, underwater pumps or servo drives with set slots.

In addition to individual production, our comprehensive range of services and product portfolio also includes stand-alone machines that can be individually combined to form automatic production cells. We offer fully automated production lines especially for the requirements of series production. The manufacturing solutions from Schaeffler ELMOTEC STATOMAT combine many years of know-how in the field of winding technology with state-of-the-art automation technology.

- Compact motor designs for highest power density

- Patented “U-Shape” technology

- Up to 10 wire jumps without the use of “special pins

- Elimination of critical manufacturing steps for maximum process reliability

- Minimal number of welding spots

With the innovative flat wire wave winding we help our customers to realize even more efficient drive concepts and to set new benchmarks in the field of power density.